The truck repair industry faces challenges from complex commercial vehicles, but AI-based tools offer substantial gains in efficiency. Leveraging machine learning algorithms, these tools predict vehicle issues and trends, enabling proactive maintenance to reduce unexpected breakdowns. They enhance diagnostic accuracy, streamline repairs, and minimize labor costs, revolutionizing the industry with improved productivity and customer satisfaction. Implementing AI-based tools requires a strategic approach focusing on impact areas, integration points, data quality, staff training, gradual rollout, performance monitoring, feedback gathering, and continuous process refinement.

“The truck repair industry, a cornerstone of logistics and transportation, faces unique challenges in maintaining fleet operation and safety. This article explores how Artificial Intelligence (AI) consulting services are revolutionizing this sector by offering efficient solutions. We delve into the specific challenges of the trade and present AI as a game-changer for optimization.

By implementing AI-based tools, repair shops can streamline processes, enhance accuracy, and significantly improve overall truck repair efficiency.”

- Understanding the Truck Repair Industry and Its Challenges

- The Role of AI in Optimizing Truck Repair Processes

- Implementing AI-based Tools: A Step-by-Step Guide for Success

Understanding the Truck Repair Industry and Its Challenges

The truck repair industry is a vital component of global logistics, ensuring the smooth operation of freight transportation across diverse sectors. However, it faces unique challenges due to the complexity and specialized nature of commercial vehicles. From routine maintenance to addressing intricate mechanical issues, repair shops are often pressed to balance efficiency with accuracy. The industry’s dynamic nature, characterized by evolving technologies and strict regulatory compliance, demands agile solutions.

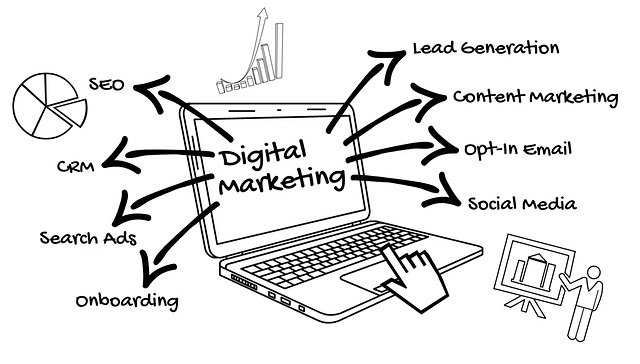

AI-based tools emerge as game-changers in this landscape, promising significant improvements in truck repair efficiency. By leveraging machine learning algorithms, these tools can analyze vast datasets from vehicle diagnostics to historical repair records, identifying patterns and trends. This predictive capability enables proactive maintenance, reducing unexpected breakdowns. Additionally, AI enhances diagnostic accuracy by providing detailed insights into potential issues, streamlining the repair process and minimizing labor costs.

The Role of AI in Optimizing Truck Repair Processes

The integration of AI into truck repair services is transforming the way workshops operate, leading to significant improvements in efficiency and productivity. AI-based tools can streamline various aspects of the repair process, from initial diagnostics to inventory management. These tools leverage machine learning algorithms to analyze vast amounts of data, enabling accurate and swift identification of vehicle issues. By providing real-time insights, AI assists technicians in making informed decisions, reducing the time spent on troubleshooting.

Furthermore, AI automation can handle routine tasks, such as scheduling maintenance checks or ordering spare parts, thereby freeing up human resources for more complex repairs. This not only enhances overall productivity but also reduces costs associated with labor-intensive processes. With AI at their disposal, truck repair services can offer faster turnaround times, improved accuracy, and enhanced customer satisfaction.

Implementing AI-based Tools: A Step-by-Step Guide for Success

Implementing AI-based tools for improving truck repair efficiency requires a strategic, step-by-step approach. Firstly, identify specific areas where AI can make an impact, such as diagnostic and maintenance prediction. Next, assess existing systems and workflows to understand integration points and potential challenges. Once ready, select suitable AI solutions based on your needs—from predictive analytics for part replacement to automated scheduling for workshops.

Ensure data quality and accessibility is a priority; AI algorithms heavily rely on accurate, comprehensive datasets. Train and educate staff on the new tools to maximise adoption and efficiency. Gradually roll out the AI-based systems, monitoring performance and gathering feedback. Regularly review and refine your processes, updating AI models as new data becomes available to ensure continuous improvement in truck repair efficiency.

AI has the potential to revolutionize the truck repair industry by streamlining processes and enhancing efficiency. By leveraging AI-based tools, repair shops can automate diagnostic tasks, improve part inventory management, and provide faster, more accurate service. Following a structured implementation guide ensures success in integrating these advanced solutions, ultimately benefiting both businesses and drivers through reduced downtime and optimized maintenance.